OEM Stamped Parts Factory – ODM Aluminum Cast communication tools – Fangchen

adjustable ipad stand, tablet stand holders。

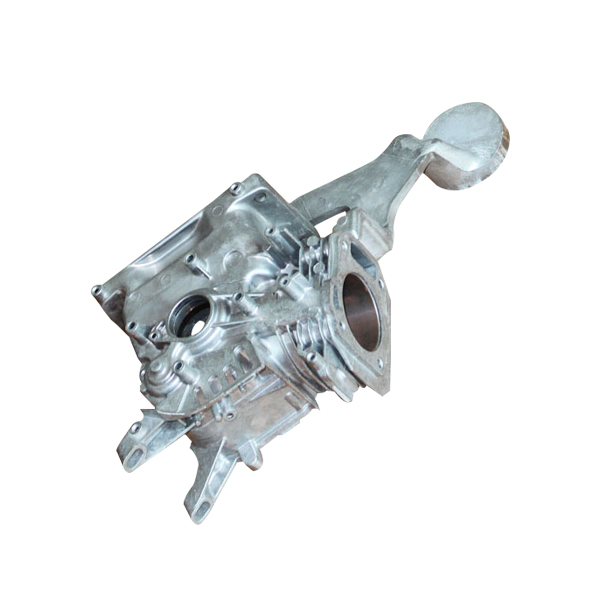

OEM Stamped Parts Factory – ODM Aluminum Cast communication tools – Fangchen Detail:

Please see our communication tools parts products they are all customized parts we make the dies and make products for customers .

Ningbo FANGCHEN is an OEM manufacturer, mainly for casting parts, CNC machining parts and sheet metal stamping parts. We have wide experience in producing and exporting metal parts, not only for OEM parts but also have the professional team for ODM.

For casting process parts, FANGCHEN has the in-house chemical and physical inspection equipment such as carbon-silicon analyzer, spectrometer, digital display universal tension machine, induction and resistance furnaces. Die casting equipment is from 180 ton to 900 ton pressure machine. The main casting processes are the sand casting for iron, aluminum, brass parts; Die casting for aluminum alloy and zinc alloy parts; Gravity casting and investment casting processes for aluminum, magnesium alloy, copper, steel and other metal parts.

We use common materials are ADC12, A380 and A360. Other materials also can be customized based on client’s requirements . We have stable Material supplier in Shanghai and Jiangsu Province . Every time material get into our factory we will make the inspection of the material elements and leave record for future trail .

Our step to make the parts for customer as follow :

1-Get confirmation of the the customized Drawing

2-Start the design of the die

3-Make the die meanwhile analyze on the surface treatment

4-After Die ready make trail

5-Get the samples and make CMM inspection by following the Customized Drawing

6-After CMM report given “green light” , send samples to customer end for checking

7-After customer confirm the final parts , we will make the trail production like 100-1000 for first order

8-After customer confirm the trail production , we will follow customers order for future produce

1. Can we get your free samples?

A. For the samples in our stocksize, sure, we’d love to provide you for free to test the quality, but hope you can bear the Freight cost.

B. For the customized samples, we can also open a new mould as your requests, but hope you can bear this samples cost.

2.What is the normal lead time?

A. For stock products, we will send goods to you within 1~7days after receiving your payment.

B. For mass production, lead time is around 30~40days, and longer if need open new mould.

3. Shipping

A. For small trial order,FEDEX, DHL, UPS, TNT etc can be provided.

B. For larger order,we can arrange shipment by sea or by air according to your requirement

Product detail pictures:

Related Product Guide:

Our business aims to operating faithfully, serving to all of our clients , and working in new technology and new machine continuously for OEM Stamped Parts Factory – ODM Aluminum Cast communication tools – Fangchen , The product will supply to all over the world, such as: Montreal, Guinea, Malta, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we've been striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.