OEM Cnc Machine Die Casting Factory – ODM Aluminum cast Commodity for sale – Fangchen

adjustable ipad stand, tablet stand holders。

OEM Cnc Machine Die Casting Factory – ODM Aluminum cast Commodity for sale – Fangchen Detail:

What is Cast Aluminum?

Cast aluminum is created when aluminum is heated to extremely high temperatures. The molten aluminum is then molded into a shape and cooled to craft a wide variety of products.

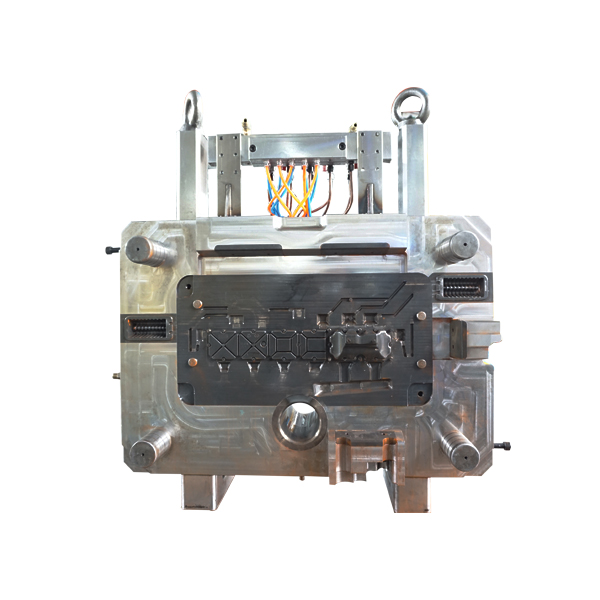

To prepare the manufacturing of cast aluminum parts, the mold must be made with precision because it’s quality will have a direct impact on the shape and surface finish of the finished aluminum casting.

The mold can be made from many different materials, including tool steel, because aluminum has a lower melting point than steel. Another material that a mold can be made out of for aluminum casting is sand. For this, the sand is pressed to take the form of the desired finished part. Once the sand is formed, the liquid aluminum is poured into it and allowed to cool.

Cast aluminum parts have properties similar to other aluminum components. Once the casting process is complete the aluminum castings quickly form an exterior layer of aluminum oxide that helps protect against corrosion.

Please see commodity are all customized parts we make the dies and make products for customers .

FANGCHEN has a professional and senior mold engineering team, providing optimal mold solution to customers based on their requirements in order to guarantee the products quality and mold life.

Commodity usually g need to use our 400-800T machine to produce.We can mass produce the parts with thin wall thickness as 1.0mm.We have accumulated rich experience on internal porosity and air tightness control in thick-wall die casting parts.

We use common materials are ADC12, A380 and A360. Other materials also can be customized based on client’s requirements . We have stable Material supplier in Shanghai and Jiangsu Province . Every time material get into our factory we will make the inspection of the material elements and leave record for future trail .

Our step to make the parts for customer as follow:

1-Get confirmation of the the customized Drawing

2-Start the design of the die

3-Make the die meanwhile analyze on the surface treatment

4-After Die ready make trail

5-Get the samples and make CMM inspection by following the Customized Drawing

6-After CMM report given “green light” , send samples to customer end for checking

7-After customer confirm the final parts , we will make the trail production like 100-1000 for first order

8-After customer confirm the trail production , we will follow customers order for future produce

Fangchen workers follow the steps strictly , every step can be trail if any problem on the products were find we can find out the problem and solve the problem in short time .

Product detail pictures:

Related Product Guide:

Assume full responsibility to satisfy all needs of our clients; achieve continual advancements by endorsing the expansion of our purchasers; turn into the final permanent cooperative partner of clientele and maximize the interests of clients for OEM Cnc Machine Die Casting Factory – ODM Aluminum cast Commodity for sale – Fangchen , The product will supply to all over the world, such as: Philadelphia, Slovenia, Kazakhstan, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we'll continue to develop, to deliver the high-quality items and services, and promote lasting cooperation with our customers, common development and create a better future.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!