OEM Automotive Injection Moulds Manufacturers – Die casting mould with material of H13, Die-var, DAC – Fangchen

adjustable ipad stand, tablet stand holders。

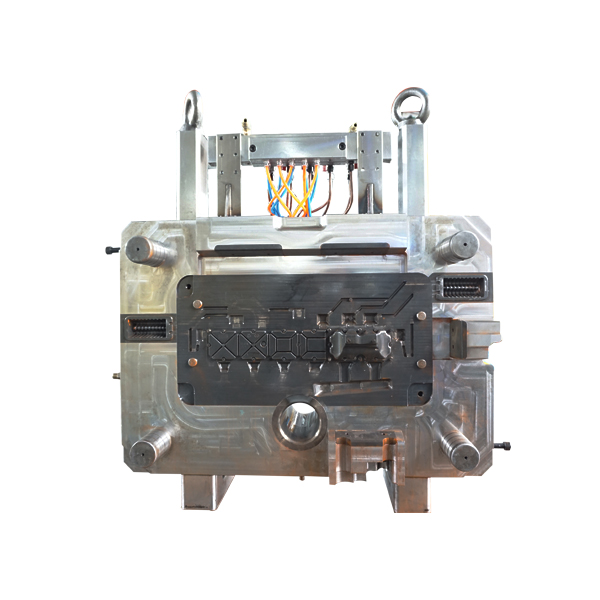

OEM Automotive Injection Moulds Manufacturers – Die casting mould with material of H13, Die-var, DAC – Fangchen Detail:

Please see our LED Cover products they are all customized parts we make the dies and make products for customers .

FANGCHEN has a professional and senior mold engineering team, providing optimal mold solution to customers based on their requirements in order to guarantee the products quality and mold life. As the LED cover with powerful heat dissipation system , the mould is very hard to make and keep long life time . We make the dies with MEGAMA Flow system . And after the simulation result get without any problem we go for die design .

LED cover usually are big need to use our 800T-1250T machine to produce.We can mass produce the parts with thin wall thickness as 1.0mm.We have accumulated rich experience on internal porosity and air tightness control in thick-wall die casting parts.

We use common materials are ADC12, A380 and A360. Other materials also can be customized based on client’s requirements . We have stable Material supplier in Shanghai and Jiangsu Province . Every time material get into our factory we will make the inspection of the material elements and leave record for future trail .

Our step to make the parts for customer as follow :

1-Get confirmation of the the customized Drawing

2-Start the design of the die

3-Make the die meanwhile analyze on the surface treatment

4-After Die ready make trail

5-Get the samples and make CMM inspection by following the Customized Drawing

6-After CMM report given “green light” , send samples to customer end for checking

7-After customer confirm the final parts , we will make the trail production like 100-1000 for first order

8-After customer confirm the trail production , we will follow customers order for future produce

Fangchen workers follow the steps strictly , every step can be trail if any problem on the products were find we can find out the problem and solve the problem in short time .

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for OEM Automotive Injection Moulds Manufacturers – Die casting mould with material of H13, Die-var, DAC – Fangchen , The product will supply to all over the world, such as: United Arab emirates, Serbia, Mauritania, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.